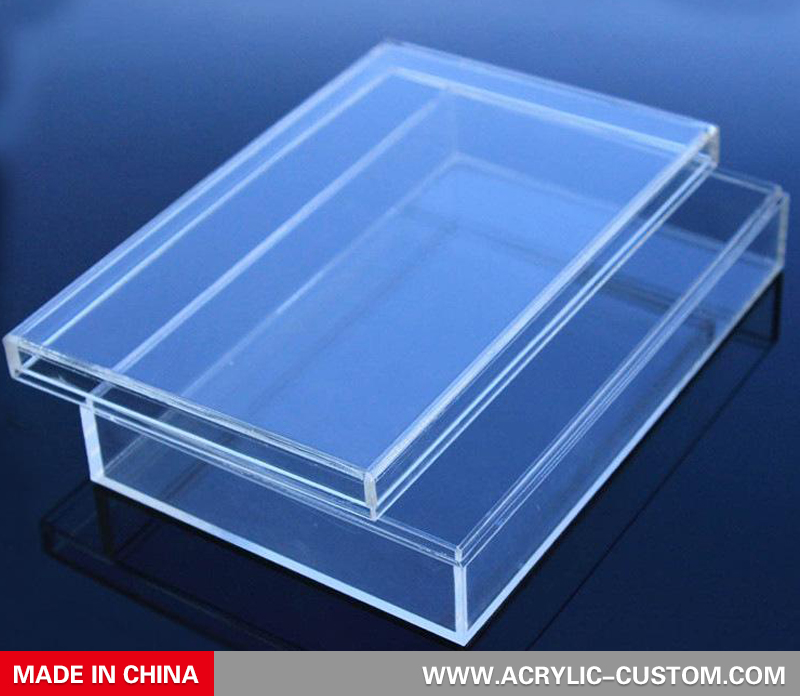

Friends who have a certain understanding of acrylic products know that products made of acrylic materials are not only beautiful in appearance, but also have very good overall performance.

In the production process of acrylic boxes manufacturers, if they do not have enough technical experience, they may cause product deformation materials to burst, thereby affecting the overall use and aesthetics. So how should manufacturers avoid these problems in the production process?

First of all, before the box is made, the appropriate sheet thickness should be selected according to the actual size of the product required. Generally, the larger the bearing area, the thicker the sheet thickness required. Only in this way can it be better in the use process. Improve its load-bearing capacity to avoid deformation.

Secondly, avoid contact with high temperature during production to avoid deformation. Because acrylic itself is not resistant to high temperatures, special care must be taken in temperature control.

To improve the impact resistance of the acrylic boxes during the production process, simple thermoforming acrylic processing methods can be used directly to make it, which can avoid the size change after moisture absorption, and can also increase the internal stress of the board.